Serpentine

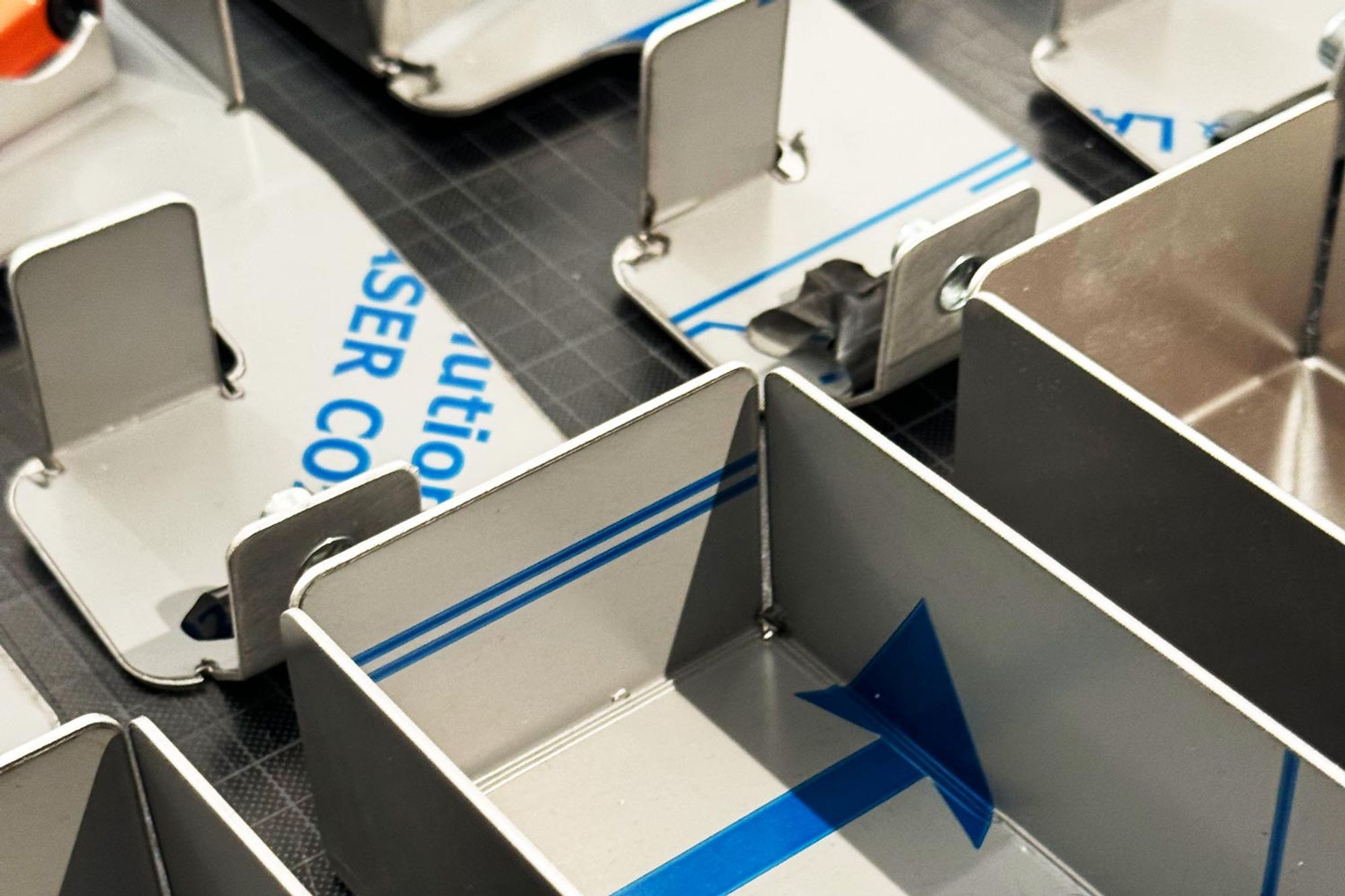

Product Design, 2024The vision of local production: CNC-bent sheet aluminum lamp with clamping mechanism for accentuated lighting.

The idea of collaborative industry

The vision of collaborative industry proposes a local production culture based on open-source digital files, computer-aided production methods and the concept of makerspaces, which are going to be found in every major city within walking distance. By opening up designs for modification and tampering, something that could be called participatory consumation might emerge. The automatically acquired understanding flattens the hierarchy between producer and consumer and aims to create a conscious and responsible balance between production and consumption.

Proof of concept?

The Serpentine lamp attempts to turn this vision into reality. The clamp mechanism as well as the lampshade and the holder for the E14 socket are laser-cut from a single sheet of aluminum that is precisely CNC-bent. The data for the housing and a parts list are openly accessible and can be produced/ordered from local or international suppliers for digital manufacturing. As it is an open source system, ideas and requests can be designed, submitted and negotiated in a conversational setting. With a few simple steps, Serpentine can be assembled anywhere. The prototypes for Serpentine were produced by the Austrian manufacturer Kovac-Stahl, for example.

Assembly

Serpentine is made of 1.5 mm thick aluminum sheet. While the prototype has no surface treatment to increase the patina friendliness, powder coatings, anodizing, etc. are an option. Apart from the actual aluminium housing, 4 other standard parts are required. An M8 rivet nut, a clamping lever with the matching foot and the wiring. The only manual work step is to insert the M8 rivet nut through which the clamping mechanism can be screwed.

Credits

Design by Leo Mühlfeld. Thanks to Matthias Pfeffer for engineering advice.